Coax

AMETEK SCP provides coax assemblies and connections for deep submergence subsea environments. Our subsea coax cable assemblies utilize our knowledge of glass-to-metal seals and protective over moldings, such as polyurethane. Our Subsea Coax Products enjoy wide usage in many diverse applications because they have been designed for the harshest environments and best technical performance. In addition, we provide pre / post-sales support, custom solutions, shorter delivery times, and competitive prices.

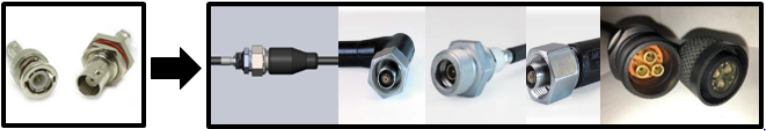

We use industry-standard communication technology to manufacture a ruggedized connector for harsh environments

AMETEK SCP does not offer a “one size fits all” coax cable assembly product. Every order is tailored to your specifications: choice of backshell, choice of cable, and more.

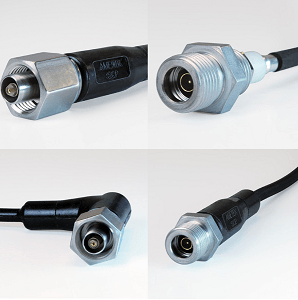

The picture on the right shows multiple Coax connections in a single housing. Our standard connector backshell is constructed from Stainless Steel 316/316L. For even more demanding applications we offer specialty metals, e.g., Titanium. If needed, we can provide certification of pressure testing to specific ocean depths.

Your Cable choice matters greatly too for your subsea coax cable assembly. The picture on the left shows a cable assembly constructed with Pressure Balanced Oil Filled (PBOF) cables which are used in the most demanding applications. And we will terminate your assembly to your specified length of cable. We support many popular cables: RG-58/142/174/180/316, LMR-195/240, CN-4, IW-1603, and others. We will develop a solution for any cable you wish. Polyurethane overmolding is standard, but we can offer your choice of overmolding material as required.