Accessories and Services

Nautilus Marine Service offers a broad range of services and accessories to support the customization of instrument spheres.

VITROVEX glass spheres can be provided with mounting flanges made of Titanium, Stainless steel, and plastic as an alternative solution to open and close spheres as easily as accustomed non-glass enclosures.

Supplementary to vacuum port, VITROVEX instrument spheres can be provided with a variety of drill holes and corresponding ground flat to accommodate bulkhead connectors, feed-throughs, etc. for connection to electronics and batteries inside, or releases, sensors, or other packages on the outside.

VITROVEX bulkhead adaptors offer an additional approach to realize through-wall connections. They are available for circular and low-profile connectors and provide greater flexibility for the use of glass enclosures since additional interfaces could be attached proactively and sealed with blanking plugs.

For protection, storage, and ease of handling LDPE (low-density polyethylene) protective shells are available as well as a mounting framework with swiveling sphere fixings, rope, thimbles, and shackles (EDDYGRIP system).

High-quality VITROVEX glass can also be polished to even enhance optical properties for high-resolution digital camera/video applications.

Please check out the individual parts below for more details.

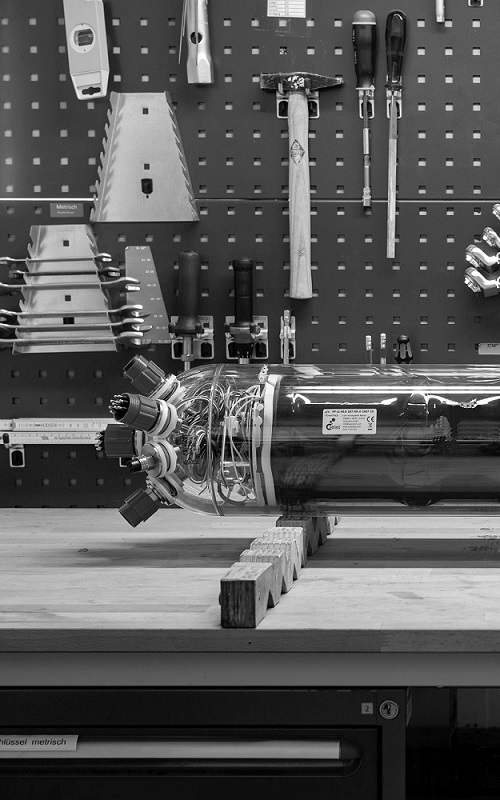

Overview

Instrumentation spheres are characterized by the fact that they are opened and closed frequently (contrary to FLOATATION spheres, which are sealed during fabrication and normally not opened during their whole lifetime), and they are different in terms of their scope of supply. A vacuum port with an accompanying drill hole is almost always installed just as one or more drill holes. Upon production process, Nautilus Marine Service, therefore, requests its drill hole specification form (DHS) to be completed for each instrument sphere to ensure total agreement with client requirements. Please see our download area to choose the appropriate DHS form.

For your choice of the most appropriate VITROVEX glass enclosure and prior to your inquiry, we would like to emphasize a few basic points which should be paid attention to in particular:

- maximum depth rating

- buoyancy (Please check our chaper on Floatation Spheres, if your interest is in positive buoyancy only.)

- inner diameter for your built-in equipment

- ribbed or smooth protective shell sets

- pressure test required?

Table 1 shows the characteristics of the most common instrumentation spheres and shall be regarded as a selection guide rather than a definitive list.

If your preferred glass enclosure is not listed, please get in touch to discuss our options for your particular application.

Nautilus Marine Service offers a broad range of services and accessories to support the customization of instrument spheres. Please check out the individual model series for details. For the best possible and efficient guidance, Nautilus Marine Service would appreciate it, when a short description/drawing of your application could be provided.

| accessories | overview | |

|---|---|---|

| Vacuum pump |  |

Deck purge box (pump) that fits vacuum ports, for evacuation of glass housings and to eliminate moisture inside. Download Datasheet: VITROVEX deck purge box |

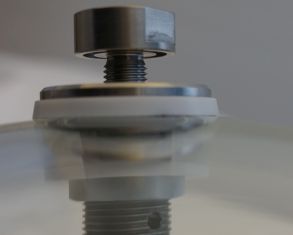

| Vacuum port (self-sealing) |  |

Titanium vacuum port, self-sealing version with 5mm or 7/16“ threaded bolt. Self-sealing vacuum ports in combination with a Deck Purge Box ease the procedure to open and closing pressure housings and eliminate any moisture inside the enclosure. Download Datasheet: self-sealing vacuum ports |

| Vacuum port |  |

Titanium vacuum port with single and double face seal and 5mm threaded bolt. Download Drawing: General arrangement Download Technical notes: Installation guidelines |

| Sealing and protective tape |  |

Scotchrap is used to protect the TEROSTAT sealing tape from mechanical damage or from any other negative impact e.g. caused by seawater. Scotchrap Tapes have a 5-year shelf life (from the date of the manufacturer) when stored under the following recommended storage conditions: Store in a clean dry place at a temperature of approx. 21°C (70°F) and 40 to 50% relative humidity. Good stock rotation is recommended.

Shelf-live becomes virtually unlimited when stored cool and dry (15°C / 40% rel. humidity). |

| Manometer |  |

Nautilus Marine Service can supply a manometer to quickly check or monitor the status of the vacuum inside the glass housing. The manometer can be bonded anywhere inside the glass enclosure and a protective shell can be modified with a viewing window in this regard.This feature can be especially useful if a last check of the vacuum is required right before deployment and time-consuming disassembling efforts of the protective shells is not an option. |

| Hose adapter for vacuum ports |  |

Hose adapter for vacuum ports. |

| Heatsink |  |

Filler plug made of Copper requires bulkhead connector ports, approx. heat flow in W @deltaT (40@20°, 60@30°, 80@40°, 100@50°). |

| Pressure feedthrough |  |

VITROVEX pressure feedthrough (high pressure 1/4″ NPT to 1/16″ NPT), made of stainless steel AISI316.Download Drawing: Pressure feedthrough |

| Pressure switch |  |

Pressure activated switch; triggers at approximately 3 bar. |

| Flanges |  |

Flanges provide an alternative solution to open and close spheres. They are often made of Titanium due to similar thermal expansion coefficients. Stainless steel or plastic flanges could also be feasible for short-term deployments or shallow-water applications. Leak tightness is achieved, similar to any other non-glass housings, by means of o-rings between two flanges. Nautilus Marine Service provides a default flange design and can also manufacture according to customers’ needs.

The glass housing is bonded to the flanges using a commercially available adhesive. For customers who like to apply their own flanges to glass housings, Nautilus Marine Service has bonding instructions available as well as corresponding tools and adhesives. Please note: In general, glass housings are very strong against pressure, but do not have the same qualities against tension or shear, or torsion. So, do not install glass housings at platforms where they are subjected to such forces. This is particularly important for housings that have been furnished with metal flanges. Do not use those flanges as mounting support on flexible surfaces. Downloads: Drawing NMS-FLA-Ti-17-I, 3D model (3D) NMS-FLA-Ti-17-I |

| Filler plugs |  |

Blanking plugs for additional outputs, even if there is no need for all holes at the time of production. |

| Bulkhead mounting sets |  |

Bulkhead adaptors offer an additional approach to realize through-wall connections and provide greater flexibility as additional interfaces could be attached proactively and sealed with blanking plugs. Available for circular and low-profile connectors.

Download Datasheet: VITROVEX connector adapter |

| Lubricant |  |

Molykote Lubricant grease O-rings and connectors before mating. |

| Mounting ring |  |

Mounting rings with or w/o threaded inserts which are supposed to be fixed (bonded) approx. 25mm below the rim of a corresponding hemisphere. Download Drawing: MR-PVC -7.5 MR-PVC-10 MR-PVC -13 MR-PVC -17 |

| Bonding Set |  |

Bonding Set to attach items to the glass wall. |

| Adaptor plates |  |

Adapter plates avoid bearing stress for standard connectors. They assure that stress is deducted over a wider area from the connector towards the glass around the edges of the drill hole. Download: technical workshop |

| Protective shells |  Download Technical note: VITROVEX protective shells Download Technical note: VITROVEX protective shells |

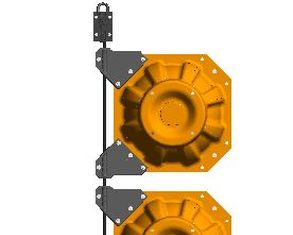

Protective shells for VITROVEX® spherical glass housings are available for impact protection, stowing, and ease of handling. They are made of LDPE (low-density polyethylene) in bright orange color and are neutrally buoyant. Protective shells are offered in a smooth or ribbed design. Each protective shell consists of two flanged halves secured by stainless steel bolts with washers and self-locking nuts. Synthetic fiber pads between the glass sphere and the shell absorb shock and retain the sphere in its position. The number of synthetic fiber pads varies with the sphere model.

Additional mounting hardware such as Eddygrip/Eddyrope swiveling sphere attachment sets is available to support field installations. Protective shells of ribbed design are often used in moorings or applications with a large likelihood for impact whereas smooth protective shells are usually used when spheres are mounted directly on underwater equipment such as landers or when the protective shell needs to be modified in order to accommodate (oversized) connectors, transducers, etc. or to provide view holes for cameras, lights, etc. respectively. There is no difference in terms of hydrodynamics or net buoyancy between ribbed and smooth protective shells. Technical drawings for protective shells are available in different formats. Please check our download section. Download: |

| Mooring system |  |

Set of up to five 17” floatation spheres attached to a braided fiber rope (Eddyrope) with swiveling mounting brackets (Eddygrip). |

| Transportation aid |  |

Experience has shown that hand-carrying heavy glass hemispheres could sometimes be challenging. The proposed lifting aid might be helpful in this regard. |

| Drill holes | Drill holes (accuracy +/- 0.2mm) and polished spotface |

| Conical drill holes | Conical drill holes (accuracy +/- 0.05mm), conical 1: 10 and 24/29mm |

| Oversized drill holes | Oversized (> 5/8″, 16.2mm) drill holes (accuracy +/- 0.2mm) and polished spotface |

| High accuracy | High accuracy drill holes (accuracy +/- 0.05mm) and polished spotface |

| Installation of Hydrophone/Transducer | Installation of acoustic transducer (e.g. PET 661G or Benthos TR/XT) |

| Installation of the bulkhead connector | Mounting of bulkhead connectors/vacuum ports incl. provision of corresponding assembly sets (non-default min. shaft length might be required) |

| Pressure test | Pressure tests, test value has to be specified and MUST NOT exceed the specification of glass enclosure nor 3rd party equipment |

| Bonding | Bonding of non-glass items such as flanges, mounting rings, etc. to VITROVEX glass articles |

| Polyurethane coating | Polyurethane coating of VITROVEX hemispheres (approx. 0.5mm width, semi-transparent white color); a free circumferential area of approx. 10mm off the equator will remain |

| Paint coating | Paint coating of VITROVEX hemispheres, windows for display of the serial number, or vacuum monitor may be kept out |

| Optical enhancement | Optical enhancement of 13″ and 17″ hemispheres; due to the production process and characteristics of glass, small bubbles, and other impurities may remain |

| Shell modification | Modification of protective shells |

| Engineering | Assistance and consulting services to turn customer-specific requirements into high-quality pressure vessels. |