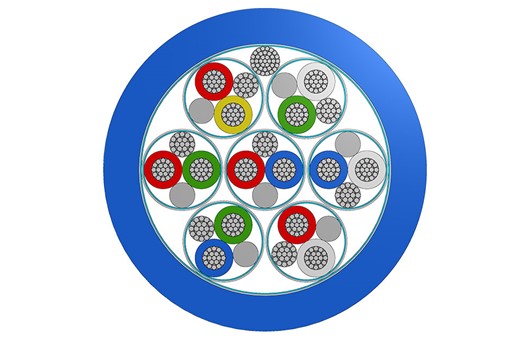

Data cable – Type 4700CC

Construction characteristics

| 7 x Screened twisted pairs | 0.50 mm² (16/0.20 mm) Tinned Copper XLPE insulated to 1.50 mm 2 of these and twisted together with Tinned Copper drain wire and filler in interstices Overall helical 12/23µm Ali/PET foil screen, minimum overlap 50% Overall helical PET isolation tape, minimum overlap 50% OD: 3.20 mm Colour: GN/WH BU/WH RD/WH GN/BU GN/RD YW/RD BU/RD |

| Lay up | and overall screen The 6 outer screened twisted pairs are twisted together around the center screened twisted pair with Tinned Copper drain wire in interstices Overall helical 12/23μm Ali/PET foil screen, minimum overlap 50% Overall helical PET binding tape, minimum overlap 50% OD: 9.90 mm |

| Jacket | Polyether Polyurethane, 85 Shore A, Halogen Free, 1.40 mm nom RTI OD: 12.70 mm +/-0.30 Colour: BU |

Mechanical characteristics

| Max. operating temp Static Dynamic |

+90°C +80°C |

| Cold flex temp | -40°C |

| Depth rating | 3,000 m |

| Min. recommended bend radius Static Dynamic |

120 mm 150 mm |

| Nominal weight In air In seawater |

210 kg/km 80 kg/km at SG 1.025 |

Electrical characteristics

| Conductors Max. conductor resistance Voltage rating Test voltage Capacitance Impedance |

38.60 Ω/km at 20°C 600 V 3,000 V DC for 1 minute 100 pF/m 57 Ω at 1-10 MHz |

| Attenuation at 4 KHz 10 KHz 1 MHz 10 MHz |

0.30 dB/100 m 0.50 dB/100 m 7.00 dB/100 m 18.00 dB/100 m |

| Min. insulation resistance Core – Core Core – Screen Screen – Screen |

> 1.00 GΩ/km > 500 MΩ/km > 10 MΩ/km |

| In compliance with | CE, UK CA, UK NI, RoHS, LVD |